Demystifying Sustainability and ESG

ESG | Sustainability | Corporate Social Responsibility | Circular Economy | Going Green

Welcome to the language of today’s supply chain. What do these terms mean for members of the industry? And how can IT asset managers make the most of these emerging trends? We will look at the escalating role that sustainability and ESG plays in the IT asset hardware space and the benefits organizations can gain from adopting them.

Setting the Context

The reverse logistics industry will be affected by two major trends over the next decade: a shift by organizations to focus their goals and priorities on ESG (environment, social and governance) and the global transition among manufacturers toward a circular economy. Let’s start with some definitions of these terms.

The term ESG is the latest buzzword in the evolution of corporate social responsibility. Investment firms are shifting billions of dollars of investor funds away from fossil fuels and towards companies that practice sustainability. They are looking for ways to invest in companies that:

- Measure and minimize their impact on the environment (E)

- Operate under strong codes of social ethics around gender equality, diversity and inclusion in their workforce and communities (S)

- Have strong policies in place around fair and equal pay, employee rights, executive compensation, and environmentally sustainable business practices (G).

Organizations large and small will be coming under increased pressure from their stockholders and customers to demonstrate their commitment to ESG principles. That means they will be looking at internal policy shifts as well as external partners that can help them achieve their ESG goals. Many are developing standards or scorecards for their supply chain partners that require them to document their progress toward these values.

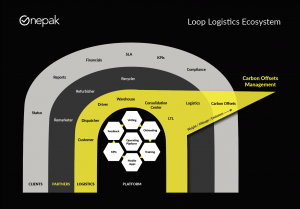

The term “circular economy” refers to the shift away from the traditional linear “take, make, waste” approach of mining virgin materials, manufacturing products for a single use and disposing of them. In a circular economy, goods are produced in a way that enables reuse and recycling of materials that will be fed back into the supply chain. For example, many IT returns are shipped using disposable cardboard. A circular model would enable a reusable package and return of that packaging to the shipper for multiple uses. Manufacturers are now being measured and rated on their “circularity.”

In these larger contexts, “going green” takes on a new meaning. It can refer to corporate initiatives to switch to renewable energy, it can include looking at the ratio of independent contractors to employees, or it can implement policies to address gender equality or racial diversity. Sustainability is not just about lowering one’s carbon footprint. It can also mean increasing one’s community impact. Key areas of environmental impact to local communities by both your company and your suppliers and vendors include: emissions, water usage, waste and ecosystems.

Weighing the Factors

Let’s translate the traditional SWOT analysis into a format that applies to this transition:

- Strengths = Reasons for moving towards sustainable business practices

- Weaknesses = Barriers that could get in the way of this transition

- Opportunities = Rewards for moving in this direction.

- Threats = Consequences of not making the transition

Reasons for making the move – The benefits of moving toward sustainable business practices are many and may include compliance with regulation, increased customer satisfaction, employee goodwill, better brand image and a happier board of directors. And let’s not forget reduced waste and reduced costs.

Barriers to entry – Organizations considering a transition to sustainable business practices may not find it easy. First, the chances of success are highest when buy-in is attained at the highest levels of your organization. However, if your executive team is not yet ready to take the next step, you as an IT asset manager can certainly implement more sustainable business practices within your purview. Second, finding opportunities that are measurable can be a challenge. There is a plethora of greenwashing out there, and it is often difficult to know what is true.

Consequences of not making the move – What happens if you don’t make the transition to sustainable business practices? You could lose customers to organizations that are taking a more proactive approach to environmental, social or governance issues. You run the risk of alienating investors who finally see ESG as mandatory. Every department in your organization has a role to play in making progress toward net-zero goals. IT asset management can either lead, follow or be humiliated without a plan of action for contributing meaningfully. Where do you want to be?

Rewards for the transition – The rewards of embracing a transition to sustainability and ESG values will compound over time. Progressive companies will attract forward-thinking investors, team members and customers. ESG-oriented vendors will want to do business with you. Your organization can be run more efficiently and your community standing will be enhanced. And as an individual, you will be welcome in the multitude of new sustainability groups where you can share ideas and learn from your peers.

Next Steps

There is a lot to know about sustainability and ESG, and it is changing constantly. There are organizations creating standards to measure ESG that are used by your investors, supply chain partners and customers. Common impact areas addressed by these standards include: greenhouse gas emissions (GHGe), forestry, water, waste & pollution, worker safety, jobs impact, total materials used, use of recycled materials, package/product lifecycle management and circularity. Most standards relate activities to the widely accepted UN Sustainable Development Goals. Leading standards organizations that are developing best practices in which your organization may be participating include GRI, SASB and CDP, a not-for-profit charity that runs a global disclosure system for investors, companies, cities, states and regions to manage their environmental impacts. Your challenge is to educate yourself so that you can make a meaningful contribution using whatever influence or power you have at your disposal.